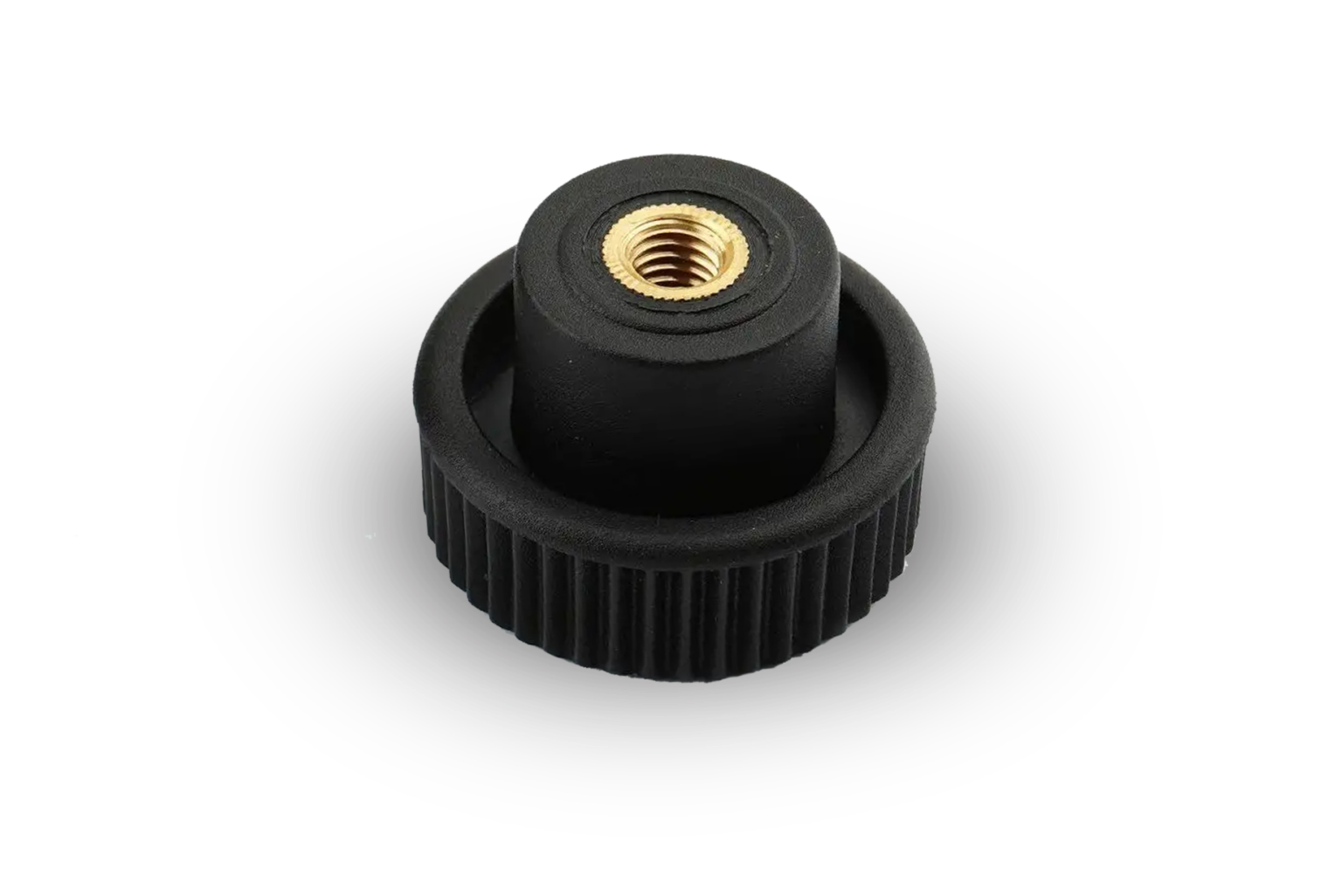

Precision insert molding is a manufacturing process that combines metal or plastic inserts with thermoplastic materials to create integrated components. This process allows for the efficient production of complex parts with improved strength, durability, and functionality. Expert insert molding services provide high-quality solutions for a wide range of industries, from automotive and aerospace to medical devices and consumer electronics.

The Benefits of Expert Insert Molding

By integrating inserts directly into the molding process, manufacturers can reduce assembly time and costs while ensuring consistent product quality. This precise method of manufacturing results in components that are more reliable, durable, and resistant to wear and tear. Expert insert molding services can accommodate a variety of inserts, including threaded fasteners, pins, bushings, studs, and electrical contacts, making it a versatile option for a wide range of applications.

Customization and Precision

One of the key benefits of expert insert molding is the ability to customize components to meet specific design requirements. Manufacturers can choose from a variety of materials, including metals, plastics, and composites, to achieve the desired strength, conductivity, flexibility, and thermal properties. This customization allows for the creation of components that are tailored to the unique needs of each application, whether it’s a high-performance automotive part or a delicate medical device.

Precision and Control

Expert insert molding services also offer designers a high degree of precision and control over the molding process. By using advanced tooling and automation technologies, manufacturers can achieve tight tolerances and intricate geometries with minimal waste and scrap. This level of precision ensures that components meet the strictest quality standards and perform reliably in demanding applications.

Streamlining the Manufacturing Process

In addition to enhancing product performance, expert insert molding can also streamline the manufacturing process. By consolidating multiple components into a single part, manufacturers can reduce material and labor costs, assembly time, and the risk of errors. The result is a more efficient and cost-effective production process that can help companies stay competitive in today’s fast-paced market.

Scalability and Flexibility

Furthermore, expert insert molding services provide manufacturers with the flexibility to scale production to meet changing demand. Whether it’s a small batch of prototypes or a large volume production run, insert molding can accommodate a wide range of production volumes without sacrificing quality or cost-effectiveness. This scalability makes it an ideal solution for companies looking to bring new products to market quickly and cost-effectively.

Conclusion

Overall, expert insert molding offers a high-quality manufacturing solution for producing integrated components with superior performance and reliability. By leveraging advanced technologies and materials, manufacturers can create customized parts that meet the unique requirements of their applications. With its ability to streamline production, reduce costs, and improve product quality, insert molding is a valuable tool for companies looking to achieve success in today’s competitive marketplace.