Custom injection molding is a specialized manufacturing process that involves creating custom molds to produce parts and products based on specific designs and requirements. This precision engineering technique allows for the creation of unique and tailored components that meet the exact needs of a particular project.

The Custom Injection Molding Process

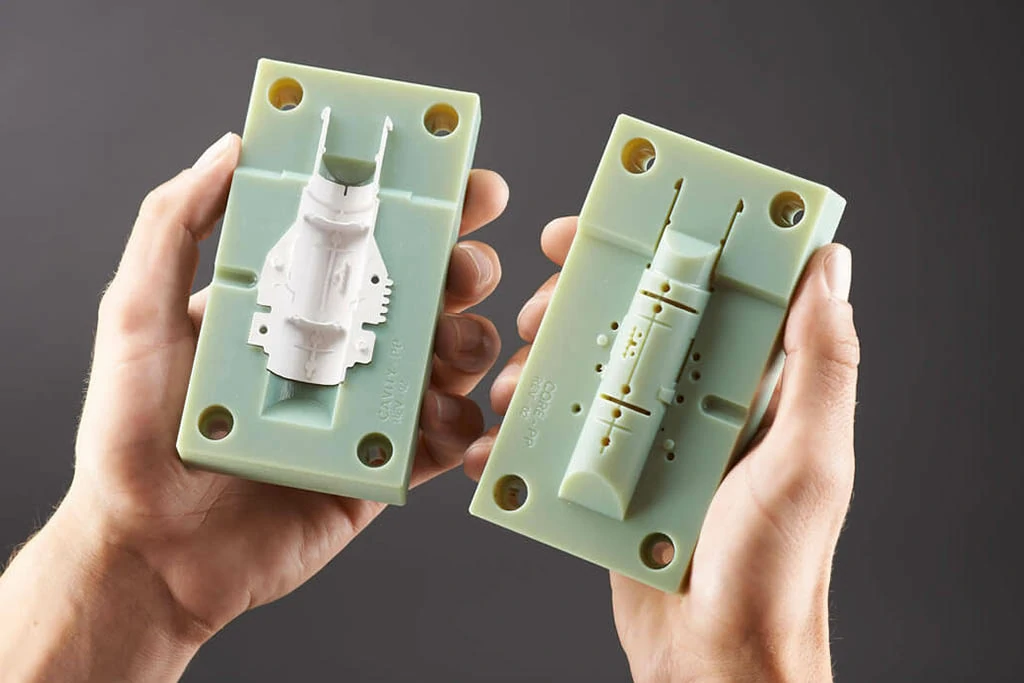

The custom injection molding process begins with the design and creation of a custom mold that will be used to form the desired part. This mold is typically made from steel or aluminum and is carefully machined to match the precise dimensions and specifications of the final product. The mold is then installed in an injection molding machine, which heats and injects molten plastic material into the mold cavity.

Advantages of Custom Injection Molding

One of the key advantages of custom injection molding is its ability to produce complex and intricate shapes with high precision and accuracy. This makes it an ideal manufacturing solution for projects that require intricate details, sharp angles, or specific geometries. By using a custom mold, manufacturers can ensure that each component is produced with consistent quality and uniformity.

Flexibility and Customization Options

Custom injection molding also offers flexibility and customization options that are not available with other manufacturing processes. Designers and engineers have the freedom to create unique shapes and features that are tailored to the specific requirements of the project. This allows for the creation of innovative and customized products that stand out in the market.

Cost-Effective Solutions for High-Volume Production Runs

In addition to precision and customization, custom injection molding offers cost-effective solutions for high-volume production runs. By using a custom mold, manufacturers can significantly reduce the time and cost associated with producing large quantities of parts. This scalability and efficiency make custom injection molding a popular choice for manufacturers looking to streamline their production processes and optimize their supply chains.

Industry Applications

Furthermore, custom injection molding is ideal for a wide range of industries and applications. From automotive and aerospace to consumer goods and medical devices, custom injection molding can be used to produce a diverse array of products that meet strict quality and performance standards. Whether it’s creating components for electronic devices or manufacturing parts for industrial machinery, custom injection molding provides a reliable and efficient manufacturing solution.

Conclusion

Overall, custom injection molding offers a combination of precision engineering, customization, and cost-effectiveness that make it a valuable tool for meeting the unique manufacturing needs of a wide range of industries. By leveraging the benefits of custom molds and advanced injection molding techniques, manufacturers can produce high-quality products that meet the exact specifications and requirements of their projects.

Final Thoughts

In conclusion, custom injection molding is a versatile and reliable manufacturing solution that allows for the production of tailored components with precision and efficiency. Whether it’s creating complex shapes or high-volume production runs, custom injection molding offers a range of benefits that can help manufacturers optimize their production processes and deliver quality products to the market.