Aseptic filling is a critical process in the pharmaceutical and food industries that ensures products are free from contamination by harmful microorganisms. Aseptic filling lines are designed to maintain sterility throughout the filling process, from the preparation of product containers to the sealing of the final product.

The Filling Machine: A Critical Component

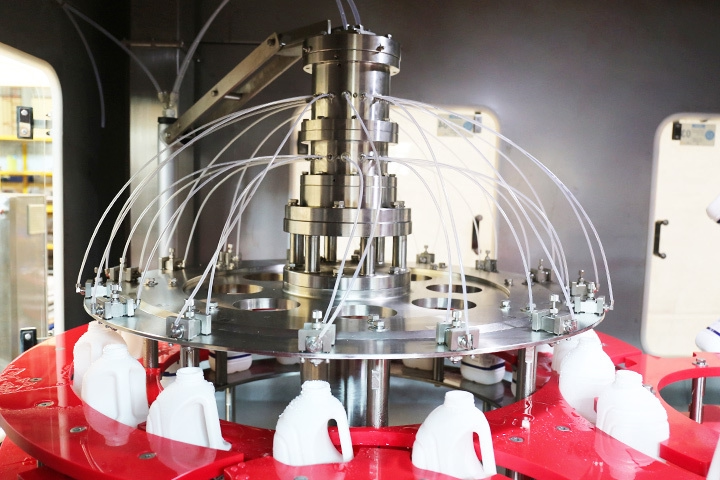

There are several key components of an aseptic filling line that work together to achieve the highest levels of sterility. One of the most important components is the filling machine itself, which is responsible for accurately dispensing the product into containers with minimal exposure to outside contaminants. These machines are typically equipped with features such as laminar flow hoods, sterilization systems, and automated controls to ensure that the product remains sterile throughout the filling process.

Additional Components: Cleaning, Sterilization, and Isolation

In addition to the filling machine, Aseptic filling line also include components such as container cleaning systems, sterilization tunnels, and isolators. Container cleaning systems are used to remove any dirt or debris from containers before they are filled, while sterilization tunnels use heat or chemical agents to ensure that containers are free from microorganisms. Isolators are enclosed workstations that provide a barrier between operators and the product to prevent contamination.

Filtration Systems: Ensuring Product Purity

Another critical component of an aseptic filling line is the filtration system, which is used to remove any particles or microorganisms that may be present in the product before it is filled into containers. Filtration systems typically consist of multiple filters with varying pore sizes to ensure that the product is free from contaminants of all sizes. In some cases, sterile air is also used to create a positive pressure environment within the filling area to further prevent contamination.

Monitoring and Control Systems: Ensuring Quality and Safety

In addition to these components, aseptic filling lines also include monitoring and control systems to ensure that the filling process remains within specified parameters. These systems may include sensors to monitor temperature, pressure, and flow rates, as well as controls to adjust settings as needed. By continuously monitoring and controlling the filling process, operators can ensure that the product remains sterile and meets quality standards.

Conclusion: The Importance of Aseptic Filling Lines

Overall, the key components of an aseptic filling line work together to create a highly controlled environment that minimizes the risk of contamination and ensures product safety. By investing in a well-designed and properly maintained filling line, companies can reap the benefits of aseptic filling, including extended shelf life, reduced waste, and increased consumer confidence. Ultimately, aseptic filling is a critical process in industries where product safety and quality are of utmost importance, and the components of a filling line play a crucial role in achieving these goals.