Thread mills are precision tools that are essential for creating high-quality threads in various materials. These tools are designed to cut internal and external threads with accuracy and consistency, making them ideal for applications where precision threading is required.

Benefits of Thread Mills

One of the key benefits of using thread mills is their ability to produce threads that are stronger and more durable than those created by traditional tapping methods. By using a thread mill, you can ensure that your threads are cut uniformly, resulting in a tighter fit and better overall thread quality.

Flexibility and Versatility

In addition to their ability to create precise threads, thread mills also offer increased flexibility and versatility compared to other threading methods. These tools can be used to create threads in a wide range of materials, from soft metals like aluminum to hard materials like stainless steel and titanium. This versatility makes thread mills a valuable tool for a variety of industries, including aerospace, automotive, and medical manufacturing.

Selecting the Right Carbide Grade

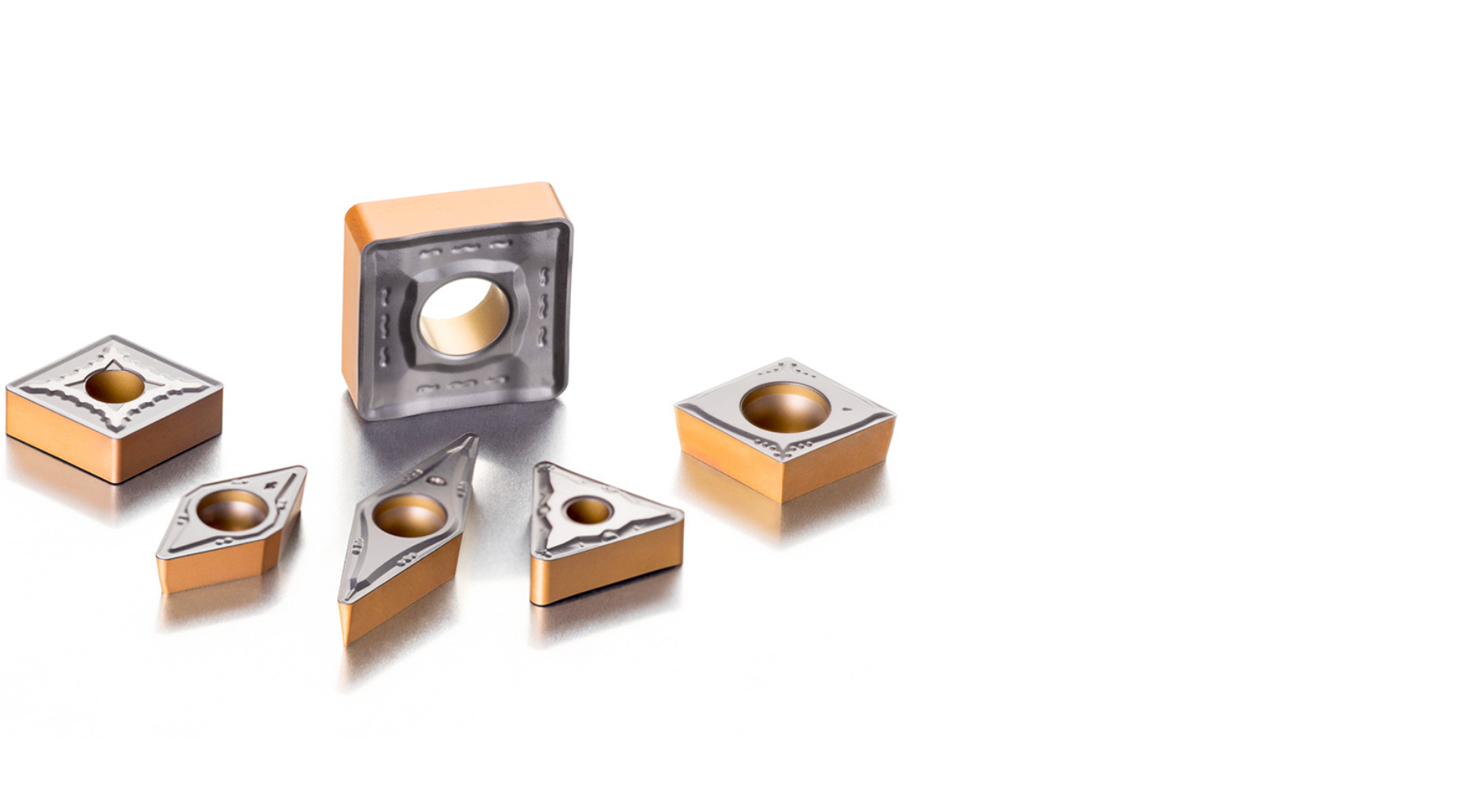

When selecting a thread mill for your specific application, it is important to consider the carbide grade of the tool. The carbide grade of a thread mill determines its hardness, wear resistance, and overall performance. Choosing the right carbide grade for your application is essential for achieving optimal tool performance and extending tool life.

Carbide Grades for Different Applications

For high-speed threading applications in soft materials, a lower carbide grade with a higher cobalt content may be sufficient. These carbide grades are more cost-effective and provide good performance in softer materials. However, for high-performance applications in hard materials like stainless steel or titanium, a higher carbide grade with added tungsten and titanium may be necessary to ensure long tool life and consistent performance.

The Importance of Coatings

In addition to the carbide grade, it is also important to consider the coating of the thread mill. Coatings like TiAlN (titanium aluminum nitride) or TiN (titanium nitride) can improve tool life, reduce friction, and enhance chip evacuation during the threading process. These coatings can also provide additional protection against machining wear and extend the overall lifespan of the tool.

Conclusion

Overall, thread mills are precision tools that offer unparalleled accuracy, consistency, and versatility for high-quality threading applications. By selecting the right carbide grade and coating for your specific application, you can ensure optimal tool performance and achieve superior results in your threading operations. Whether you are working with soft materials or hard metals, thread mills are essential tools for achieving precise and durable threads in a wide range of materials.