In today’s fast-paced and ever-evolving manufacturing industry, it is crucial to have versatile custom CNC machining services that can adapt to diverse industry applications. CNC machining plays a key role in a wide range of industries, from aerospace and automotive to healthcare and electronics. Whether you need complex components for a spacecraft or precision parts for medical equipment, having access to advanced online CNC machining services is essential to meet the demands of modern manufacturing challenges.

Advantages of Custom CNC Machining

One of the major advantages of custom CNC machining is its versatility. CNC machines can be programmed to manufacture a wide variety of parts with high precision and accuracy. Whether you need prototypes for product development or mass production of components for your assembly line, custom CNC machining can handle the job efficiently and cost-effectively. This flexibility allows manufacturers to quickly adapt to changing market demands and stay ahead of the competition.

Material Versatility in Custom CNC Machining

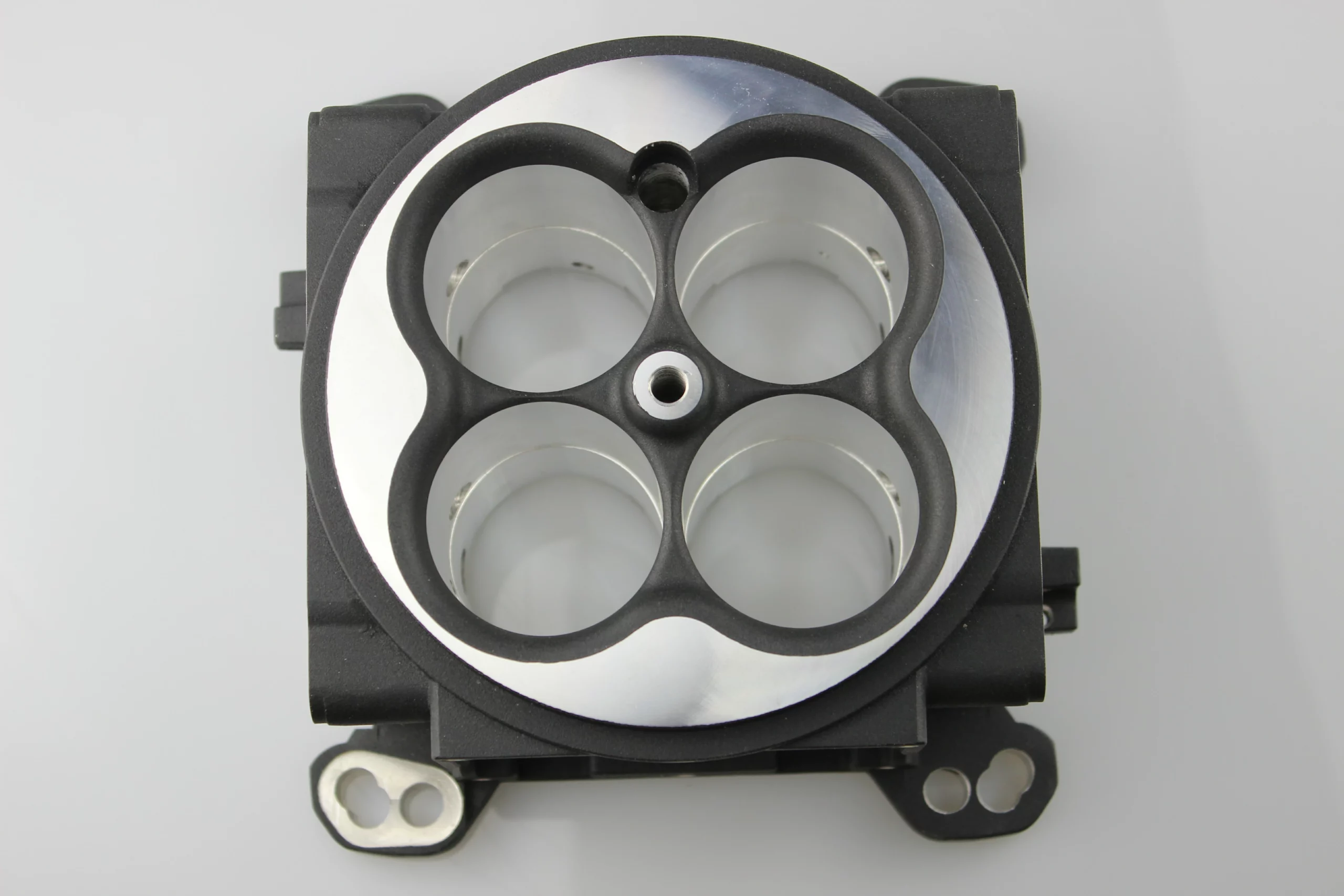

When it comes to diverse industry applications, custom CNC machining services can cover a wide range of materials, including metals, plastics, and composites. Whether you need parts made from aluminum, stainless steel, or titanium, CNC machining can handle the task with ease. From simple shapes to complex geometries, CNC machines can produce parts with tight tolerances and intricate details, ensuring that your products meet the highest quality standards.

Machining Processes for Different Industry Requirements

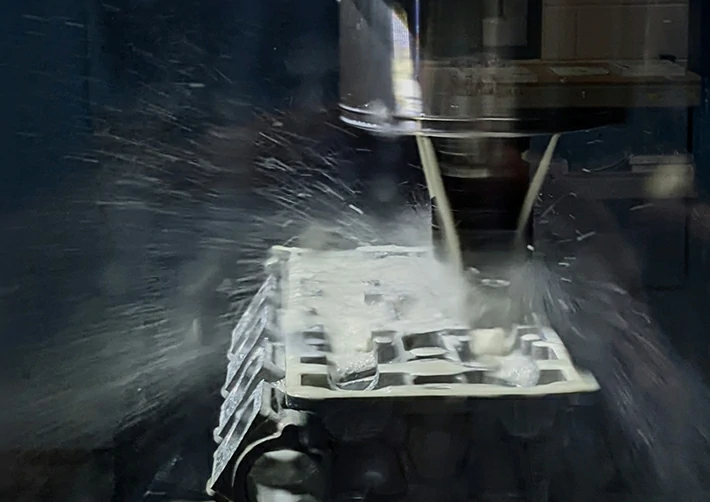

In addition to material versatility, custom CNC machining services also offer a wide range of machining processes to meet different industry requirements. Whether you need milling, turning, drilling, or grinding, CNC machines can perform a variety of operations to produce high-quality parts efficiently. This versatility allows manufacturers to streamline their production processes and reduce lead times, resulting in faster time-to-market and increased profitability.

Scalability in Custom CNC Machining

Another key advantage of custom CNC machining services is the ability to produce parts in small or large quantities. Whether you need a single prototype or thousands of components, CNC machines can handle the job with consistent quality and precision. This scalability allows manufacturers to produce parts on-demand and minimize inventory costs, resulting in a more agile and cost-effective manufacturing process.